Our Facilities

Our Facilities

- 20,000 sq. meters (Total plot area).

- 1,500 sq. meter Receiving area or raw material holding area

- 2,100 sq. meter Galvanizing plant

- 1,200 sq. meter final product holding area.

Surface Preparation and Treatment Section

Abrasive blast cleaning:

- Auto blaster: An automatic steel shot blasting unit with passage opening of 2 meter width and 1 meter height. The average capacity is 30 Tons per hour for heavy structural steels.

- Manual blasting machine: We have two point manual garnet blasting unit for odd shaped items.

Pre-treatment tanks:

Total 10 pre-treatment tanks of dimensions 13 meter (L) x 1.6 meter (W) x 3 meter (H)

- One degreasing tank

- One water rinsing after degreasing

- Five Hydrochloric for pickling

- Two water rinsing after pickling

- One pre-flux-Zinc ammonium chloride solution

Overall size 13 meter (L) x 4.6meter (W) x 4.4 meter (H). All the steel will be heated to a temperature of 80 to 100 degree centigrade before galvanizing in the Drying oven

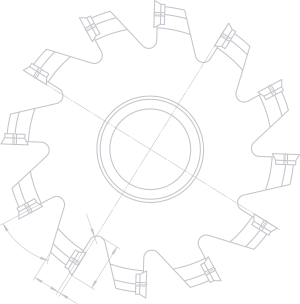

Hot Dip Galvanizing Kettle

Zinc kettle size: 13 M (Long) x 1.6M (Wide) x 3M (Deep)

Post Galvanizing Treatment Tanks

- One water quenching tank 13 meter (L) x 3 meter (W) x 3 meter (H).

- One Di-chromating tank 13 meter (L) x 1.6 meter(W) x 3 meter (H).

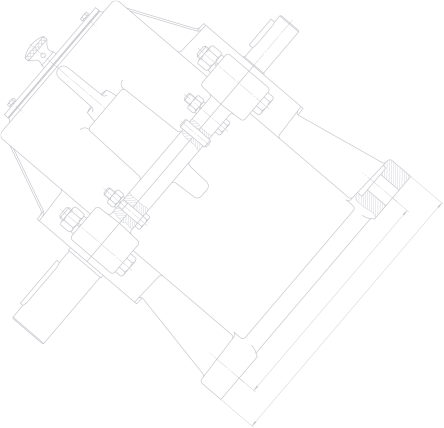

Materials Handling Equipment

- 2 units of 10 ton capacity each Goliath Cranes in the pre-treatment area.

- 3 units of 10 Tons capacity joint hoist on the mono-rail system in galvanizing area above the zinc kettle.

- 4 nos. 5 tons forklifts & 2 nos. 3 tons forklifts.

Production Capacity

5000 tons per month of heavy structural steel.